ABSTRACT

For more than three decades, Teledyne e2v has been offering to the Aerospace & Defense industry a wide range of powerful embedded processing solutions qualified for High Reliability environments (-55/125C) originally from NXP (formerly Freescale) Data Networking portfolio.

A&D industry customers are usually using several processors depending on the needs of their systems; Teledyne e2v ensures the addition of as many variants in its High Reliability processor portfolio, qualified in both RoHS (lead-free) & SnPb (leaded) finishing options.

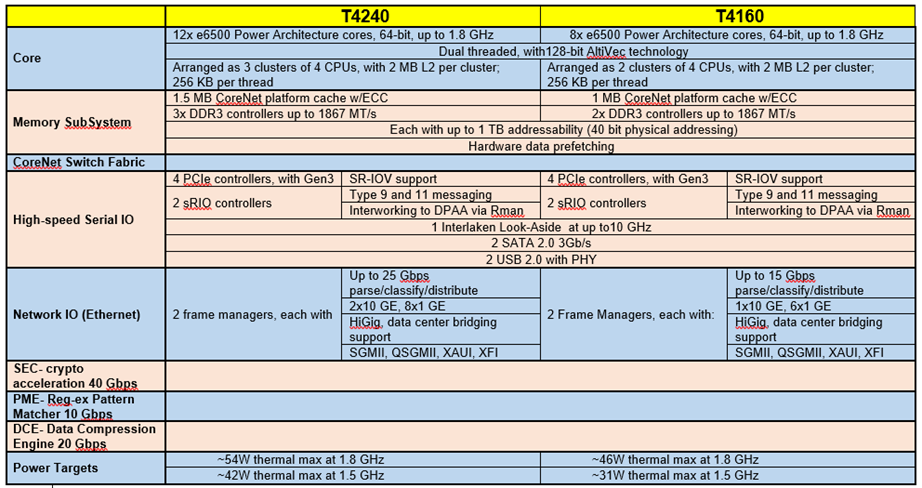

In particular, QorIQ® T4240 and T4160 communications processors (a.k.a. T4 family) are well suited for Military & Defense customers, thanks to their compute capabilities naturally brought by their combination of up to twelve dual-threaded e6500 Power Architecture® processor cores and their high level of integration offering significant space, weight and power benefits compared to multiple discrete devices.

However, the intrinsic size of the T4240 component brought significant challenges on the T4240 qualification in SnPb finishing option. Teledyne e2v offers now a fully qualified T4240 in SnPb finishing, since this option is still the preferred option from A&D customers

This paper will first highlight the key benefits brought by Teledyne e2v T4240 & T4160 High Reliability versions to Military & Defense customers, prior to illustrate the challenges of providing & qualifying components in SnPb option after Deballing / Reballing. Finally, we will highlight the utmost importance of a complete qualification of a component after deballing / reballing process.

INTRODUCTION

For more than three decades, Teledyne e2v has been providing to the Aerospace & Defense industry a wide range of powerful embedded processing solutions qualified for High Reliability environments (-55/125C) originally from NXP (formerly Freescale) Networking portfolio.

The successful differentiators from Teledyne e2v are the following :

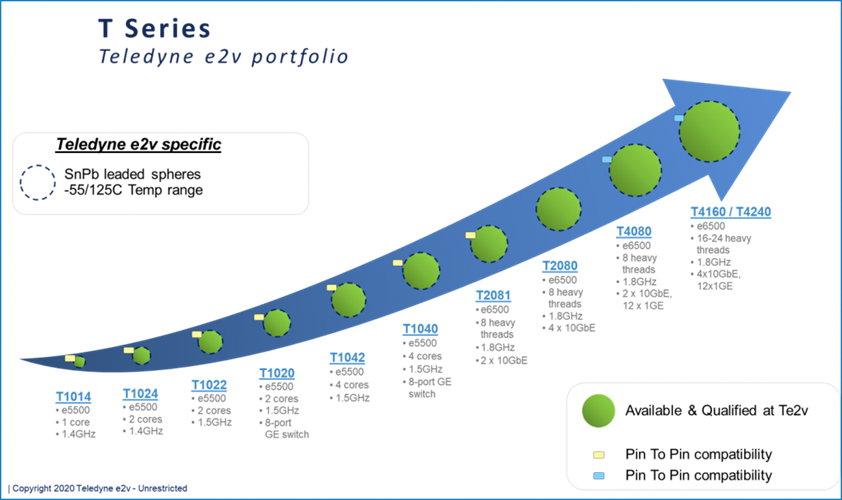

A&D industry customers are usually using a wide range of processors depending on the needs of their systems; Teledyne e2v ensures the addition of as many processor variants in its High Reliability processor portfolio, as shown in Figure 1 for QorIQ T Series Processors.

Figure 1: Teledyne e2v T Series portfolio

T4240 & T4160 : HIGH PERFORMANCE PROFILE PROCESSORS IN AN EMBEDDED POWER ENVELOPE

In particular, the QorIQ T4240 and T4160 communications processors are well suited for Military & Defense customers, thanks to their compute capabilities.

The QorIQ T4 processor family combines up to twelve dual-threaded e6500 Power Architecture processor cores with high-performance data path acceleration logic and network and peripheral bus interfaces required for networking, telecom/datacom, wireless infrastructure and mil/aerospace applications.

The T4 processor family can be used for combined control, data path, and application layer processing in routers, switches, gateways and general-purpose embedded computing systems. It delivers approximately four times the computing horsepower of the P4080 processor (highest grade of the previous P Series family of processors).

Like other QorIQ devices, the T4240’s high level of integration offers significant space, weight and power benefits compared to multiple discrete devices.

Figure 2: Teleyne e2v T4240

Figure 2: Teleyne e2v T4240

PRESENTATION OF THE T4240 & T4160

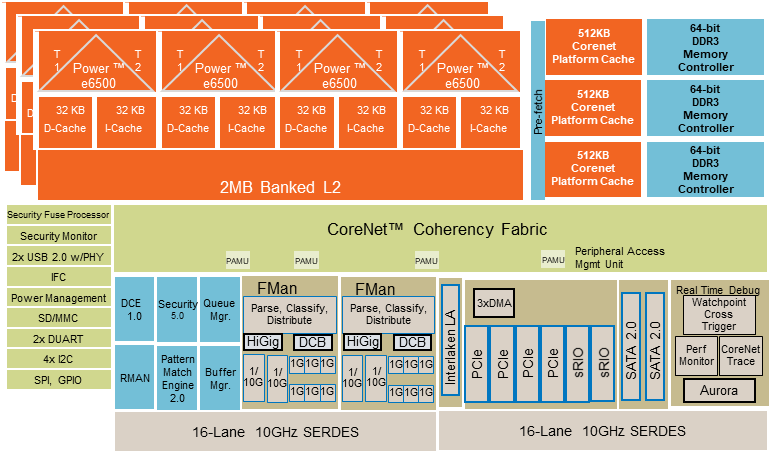

QorIQ T4240 is a 12 physical cores and 24 virtual cores, and the T4160 is an 8 physical and 16 virtual cores. With frequencies scaling up to 1.8 GHz, large caches, hardware acceleration and modern system peripherals, these products target applications that benefit from consolidation of control and data plane processing in a single SoC.

The T4240 is based on the Power Architecture e6500 core. The e6500 uses a seven-stage pipeline for low latency response to unpredictable code execution paths, boosting single threaded performance. The e6500 also offers higher aggregate instructions per clock at lower power with a “fused core” approach to threading. The e6500’s fully resourced dual threads provide1.7 times the performance of a single thread.The e6500 cores are clustered in banks of four cores sharing a 2 MB L2 cache, allowing efficient sharing of code and data within a multicore cluster. Each e6500 core implements the Freescale AltiVec technology SIMD engine, dramatically boosting the performance of media and networking algorithms, offering native inline programming and using less power than a separate DSP.

Figure 3: T4240 Block Diagram

SOLDER BALL FINISHING

Solder balls finishing is a key topic for Aerospace, Space & Defense customers. In integrated circuit packaging, the solder balls are the network of contacts underneath the device, aimed to be soldered on a printed circuit board (PCB). Systems manufacturers have been used to work with tin-lead balls (also written Sn-Pb) for many years; lead has indeed been widely believed historically to mitigate the formation of tin whiskers, though the precise mechanism is unknown. These leaded ball finishing are written SnPb, versus other type of balls not containing lead. Restriction of Hazardous Substances Directives (RoHS), which limits the inclusion of lead in most consumer products, has triggered the deployment of a tin-silver-copper solder process, also called lead-free or RoHS.

During years, manufacturers of components such as Microprocessors, were proposing both leaded (SnPb) and lead-free (RoHS) options, but since about ten years, the trend has been towards proposing only RoHS option. Since lead-free properties are less thoroughly known, they may be less popular in critical applications such as Aerospace, Space & Defense. Transition from leaded to lead-free adds naturally some lead-time for customers to adopt the lead-free technology.

Figure 4: Ball Finishing

Figure 4: Ball Finishing

Today, the adoption rate for Lead-free is higher in Europe versus other US and Asia-Pacific regions, but yet very far from being 100% to date. In Avionics & Defense systems across Europe, the run rate for lead free is still not at 100%. The adoption rate for Lead free devices is much lower in Avionics & Defense systems in both US & Asia. Therefore there is a strong market requirement to continue manufacturing and qualifying components with leaded solder finishing, which is what Teledyne e2v is offering as one of its key differentiators.

DEBALLING / REBALLING CHALLENGES ON T4240

Teledyne e2v duplicates the product configurations in order to qualify it in both RoHS & Sn-Pb ball finishing:

Such deballing / reballing process could be easily thought as just removing and replacing balls from one metal / alloy to another one (see zoom on figure 4). However the technical process is much more complex: it must indeed be carried out in a way that the full integrity of the device is completely preserved (package, substrate, silicon die, …).

While the third party process used by Teledyne e2v for deballing / reballing is qualified for various other plastic flip-chip devices, this process was not suitable for the qualification of T4240 Sn-Pb reballed version. T4240 device is indeed much bigger than standard other processors: size of the package (45mm x 45mm), and number of balls (1932 interconnects).

Some lid disbond issues were highlighted in some inspections that Teledyne e2v is performing during its qualification process. The standard reballing was actually suspected to be the root cause of the disbond issues on such a T4240 oversized component, and the first qualification trials (i.e. with standard deballing / reballing process) could therefore not be completed.

To proceed, Teledyne e2v had to select a specific and more complex deballing / reballing process for the T4240 Sn-Pb device. This led finally to a successful qualification of the Sn-Pb T4240 product option.

This above example is perfectly illustrating the importance of carrying out the complete qualification of a component on which the package has been modified, to avoid integrity issues that would not be seen without proper qualification nor inspections.

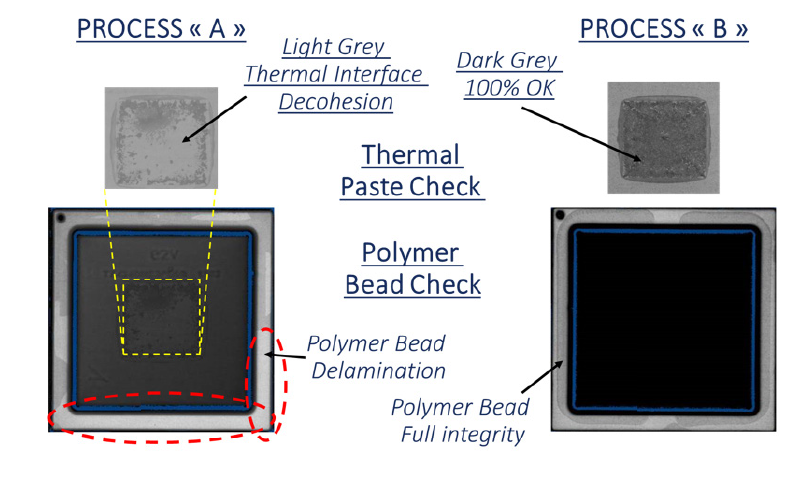

Another example is shown on Figure 5.

Figure 5: Package assembly integrity check after Deballing / Reballing (is this example, Process A is not selected)

Let’s consider a Microprocessor device that has been following a deballing / reballing to be available in leaded (Sn-Pb) option.

Figure 5 shows a same microprocessor product, on which one has been following a deballing / reballing technical

«Process A», while the other has followed a different deballing / reballing «Process B».

Once the Teledyne e2v qualification starts, an acoustic microscopy check is performed on product A and product B.

Teledyne e2v will proceed with Process B, and Process A will not be kept, as indeed not allowing to guaranty the product integrity requirements.

CONCLUSION