System-in-Package (SiP) is a common route to take in modern high-density microelectronics projects where exceptional degrees of operational reliability and elevated performance levels are going to be mandated. The principal reasons for opting for a SiP solution are simple to grasp. They are namely to make systems as small as possible and keep the power budgets involved down, while also accelerating the associated turnaround times and simultaneously dealing with far lower unit volumes than a system-on-chip (SoC) approach would be able to support.

Less upfront investment is needed with SiP and, consequently, a quicker return on investment can be realized. It also means that passive components (like inductors, filters, antennas, etc.) may be incorporated directly into the solution - which further reduces engineering effort on the customer’s side.

Integration into the customers’ system is made simpler - since thermal management issues no longer need to be worried about. When dealing with components for space deployment, assurance of radiation tolerance can be done at the SiP level, allowing the customer to offload this too.

SiP development requires aptitudes in a broad range of different disciplines. The SiP supplier needs to be able to respect acute size constraints when implementing their proposed solution. These size constraints will lead to issues in terms of thermal management and electrical interference - calling for skilled professionals with exceptional prior knowledge. Thorough testing capabilities are also vital when developing SiP hardware. This is what presents suppliers with the biggest obstacle to overcome.

Major capital outlay is needed into the software tools that facilitate SiP integration and the equipment to subsequently test the SiPs produced - and that is why Teledyne e2v Semiconductors has made a very strong commitment here. The team has access to advanced instrumentation, as well as thermal and electrical simulation technology. This is backed up by expertise with regard to packaging design and substrate bonding.

In addition, we have devoted a large proportion of our engineering resources into the development of an expansive portfolio of building blocks for SiP construction. These are not only pivotal in accelerating the completion of projects for our customers, but also mean that industry-leading benchmarks can be attained in terms of performance, solution compactness and weight reduction. If a customer needs to modify their SiP solution, it is easy for us to do so - just replacing the specific building blocks effected

Teledyne e2v Semiconductors is a trusted SiP supplier with an unmatched reputation throughout the industry. We produce SiPs that are capable of fully addressing customers’ size, weight and power (SWaP) concerns - providing compact, performance-augmented, pre-qualified solutions that are packed with sophisticated functionality.

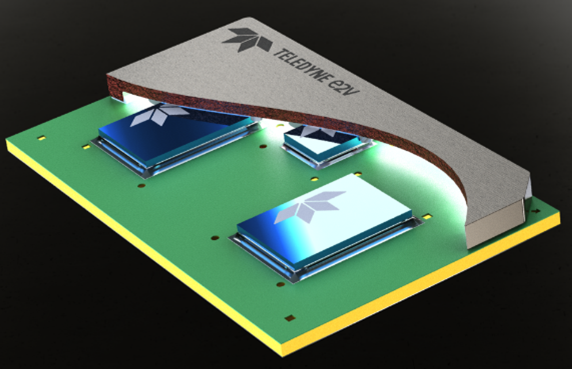

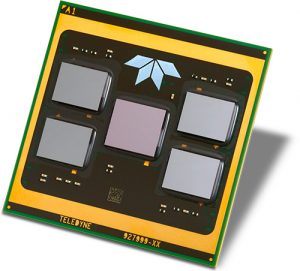

Our SiPs can incorporate numerous heterogeneous dies, based on different semiconductor technologies - with each being optimized for particular functions (such as RF transmission, signal conditioning, data processing, power delivery, data storage, image sensing and data conversion). These may include silicon-germanium (SiGe), gallium-arsenide (GaAs), gallium-nitride (GaN) and conventional silicon (Si).

Routing and substrate optimization are absolutely essential when heterogeneous dies have been integrated into a SiP. By doing this, Teledyne e2v Semiconductors can make certain that the highest signal integrity figures can be achieved, with crosstalk and distortion problems being mitigated. Also, we are almost unique to industry in our ability to work with large area dies. This allows us to accommodate FPGA devices into our SiPs.

Another key advantage of using SiPs from Teledyne e2v Semiconductors over the SoC solutions from other vendors is that a longer term supply can be secured. Through close relationships with relevant semiconductor manufacturers, and our established SLiM™ program, we have much greater lifecycle visibility. This means we are able to manage the die supply chain directly, and thereby assure continued availability. A detailed white paper on the subject of SiP can be accessed here.

Please fill out the form below to contact our sales team about our products and services.